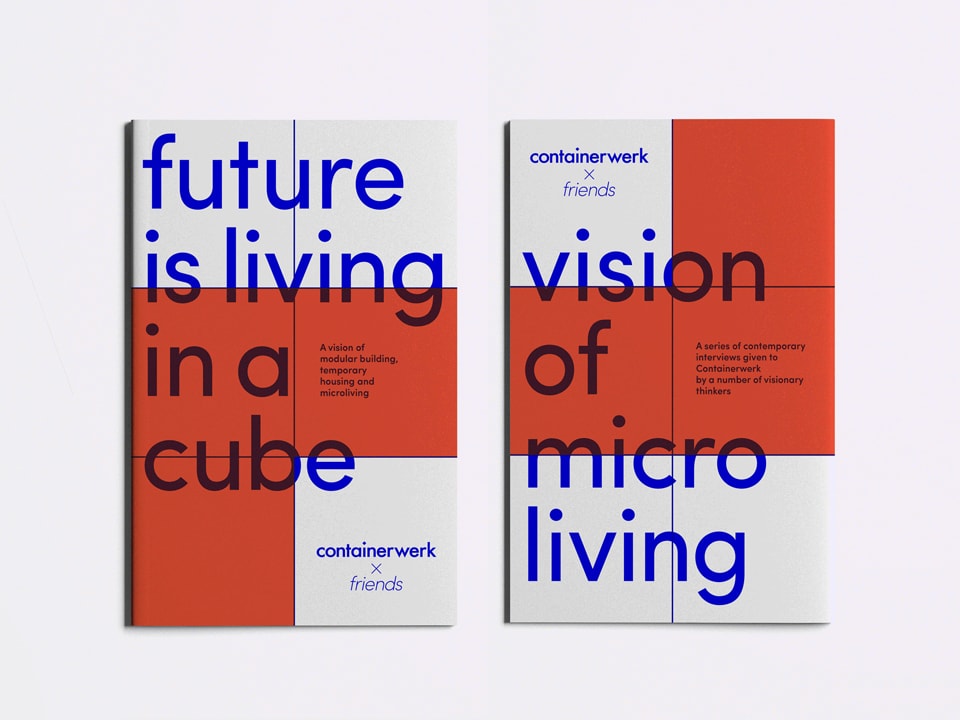

Containerwerk ist Mitglied im Forschungs- und Entwicklungsverbund der RWTH Aachen. Als Gründungsmitglied des Clusters für Modulbau im CBI erarbeitet Containerwerk gemeinsam mit anderen Modulbauern, Fachplanern und Behörden einen Genehmigungsleitfaden für modulare Bauten, um das Genehmigungsverfahren zu rationalisieren, zu verkürzen und damit Planungssicherheit zu garantieren.

Wir freuen uns sehr, dass jetzt die erste Version des Praxisleitfaden veröffentlicht wurde.

Auszug aus der Pressemeldung der RWTH Aachen zur Veröffentlichung des Leitfadens:

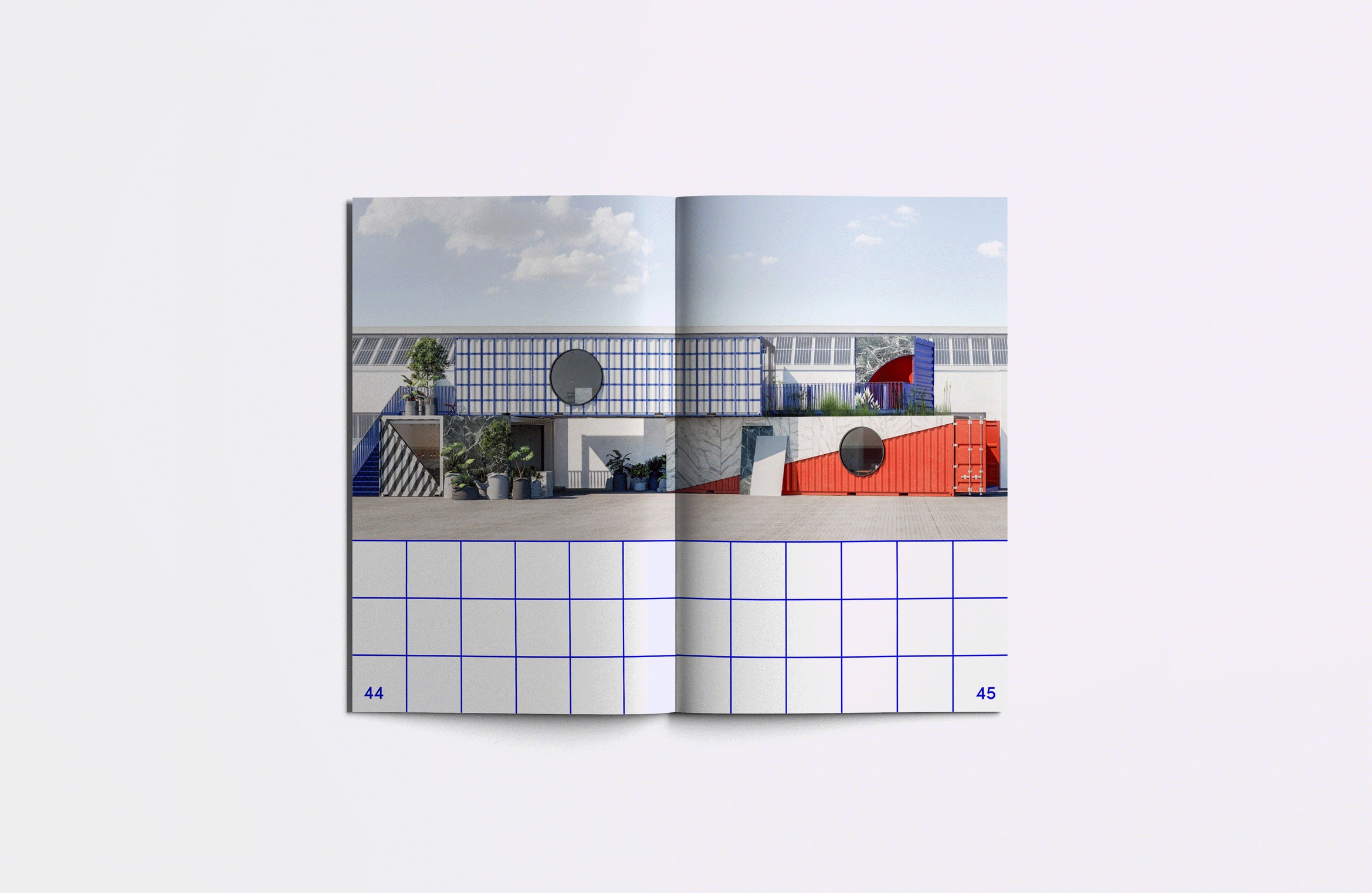

Aachen, 14. Januar 2021 – Das Center Building and Infrastructure Engineering (CBI) im Cluster Bauen auf dem RWTH Aachen Campus veröffentlicht den ersten Praxisleitfaden für brandschutztechnische Nachweise im Modulbau. Die Mitglieder im CBI – führende Raumzellen-Hersteller sowie RWTH-Experten – erarbeiteten in Kooperation mit dem Ministerium für Heimat, Kommunales, Bau und Gleichstellung des Landes Nordrhein-Westfalen innerhalb von einem Jahr ein Dokument, in dem Hinweise zum Nachweis von brandschutztechnischen Eigenschaften von Modulbaukonstruktionen komprimiert zusammengefasst wurden.

„Die Bedeutung von modularem Bauen steigt immer weiter an. Die steigenden Bevölkerungszahlen und der demographische Wandel erfordern eine schnelle und qualitätsvolle Schaffung von Wohnraum sowie von Gesundheits-, Bildungs- und Betreuungsimmobilien. Der Modulbau hat sich dabei in den letzten Jahren in vielfältiger Art und Weise weiterentwickelt. Mit dem neuen Praxisleitfaden werden Unsicherheiten für Bauherrschaften, Planer, Hersteller und Behörden in puncto Brandschutz beseitigt“, erläutert Ina Scharrenbach, Ministerin für Heimat, Kommunales, Bau und Gleichstellung des Landes Nordrhein-Westfalen.

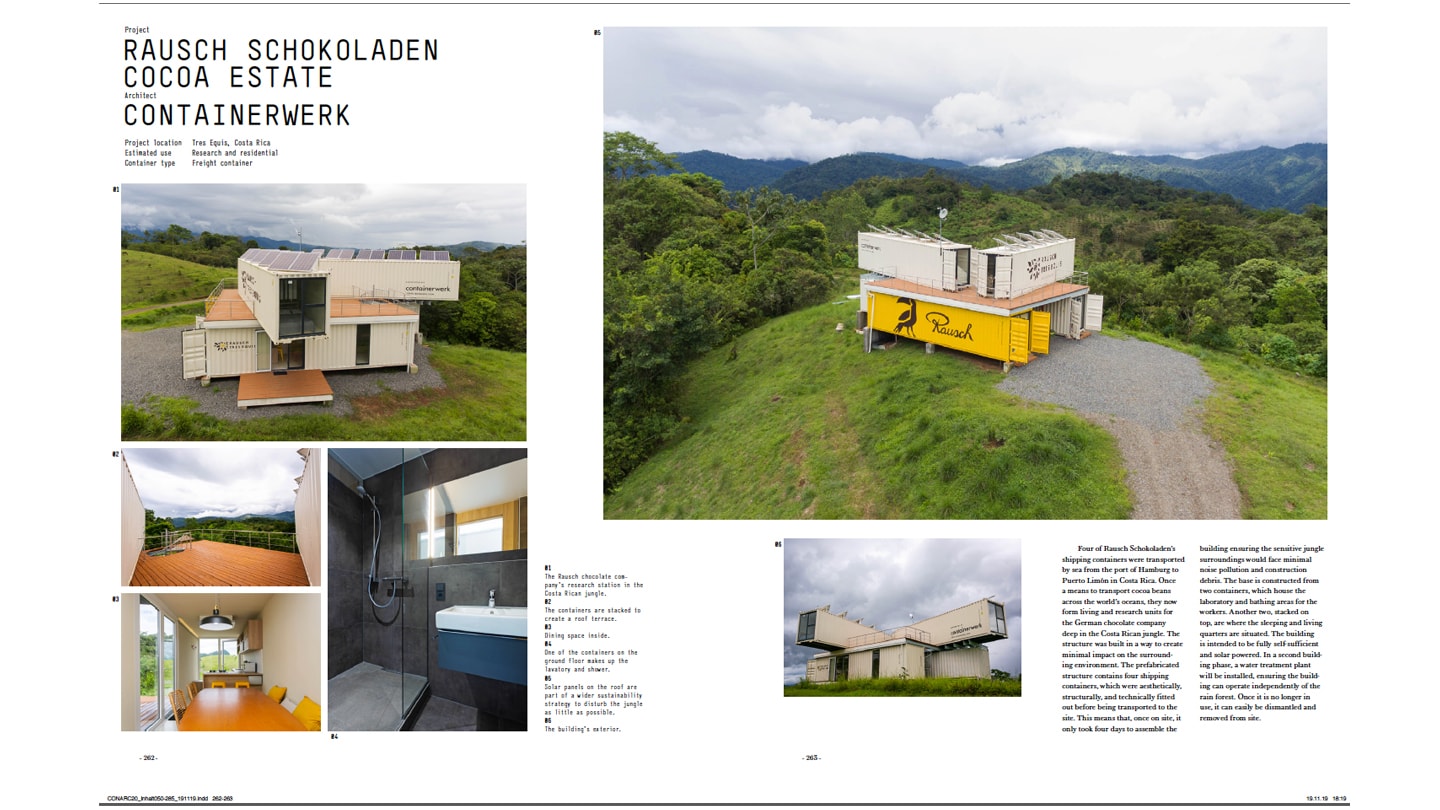

Im Center Building and Infrastructure Engineering schlossen sich Raumzellenexperten aus Wissenschaft, Wirtschaft und Landesverwaltung zusammen, um sich mit aktuellen, relevanten Herausforderungen für eine erfolgreiche Bauweise mit Raummodulen, Containern oder auch ehemaligen Seefrachtcontainern zu befassen. …

Die gesamte Pressemeldung sowie den Praxisleitfaden für brandschutztechnische Nachweise im Modulbau zum Download Finden sie auf der Website der RWTH Aachen